How can optical machine tool makers stay ahead of the competition?

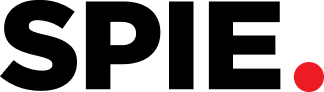

Today’s optical components require sub-micron precision, and machine tool builders face a substantial challenge keeping up with the required pace of innovation.

To stay ahead of the competition in this marketplace defined by extreme accuracies and ever stricter tolerances, machine tool manufacturers must leave no stone unturned in the search for a technological edge.

In this guide, we explore four key strategies:

-

Exploring new technologies and keeping up with the latest industry trends.

-

Leveraging suppliers capable of designing your tools using a “complete solution” approach.

-

Making use of external expertise to accelerate the deployment of new technologies and capabilities.

-

Keeping a tight focus on continuous improvement in the pursuit of superior precision.

An Optical Machine -Tool Builder’s Guide to Customizing High-Speed Spindles

In the optical industry, building, assembling, and integrating machine tools presents a unique challenge. Cutting-edge diamond-turning equipment relies on high-speed air-bearing spindles with exact specs. Standard products often fall short, requiring adaptation to meet a machine's demands. One solution? Working with a custom supplier.

In this specialty Guide for Optical Machine-Tool Builders, you’ll learn:

-

How machine-tool builders can find suppliers capable of tailoring solutions to unique objectives

-

The benefits of collaborating with custom suppliers – and why it provides a competitive advantage

-

How a fully customized spindle can streamline design, enhance machine-tool performance, and help reduce overall build costs.

Plus….explore what the future may hold for optical machine-tool builders. Just download this guide now!

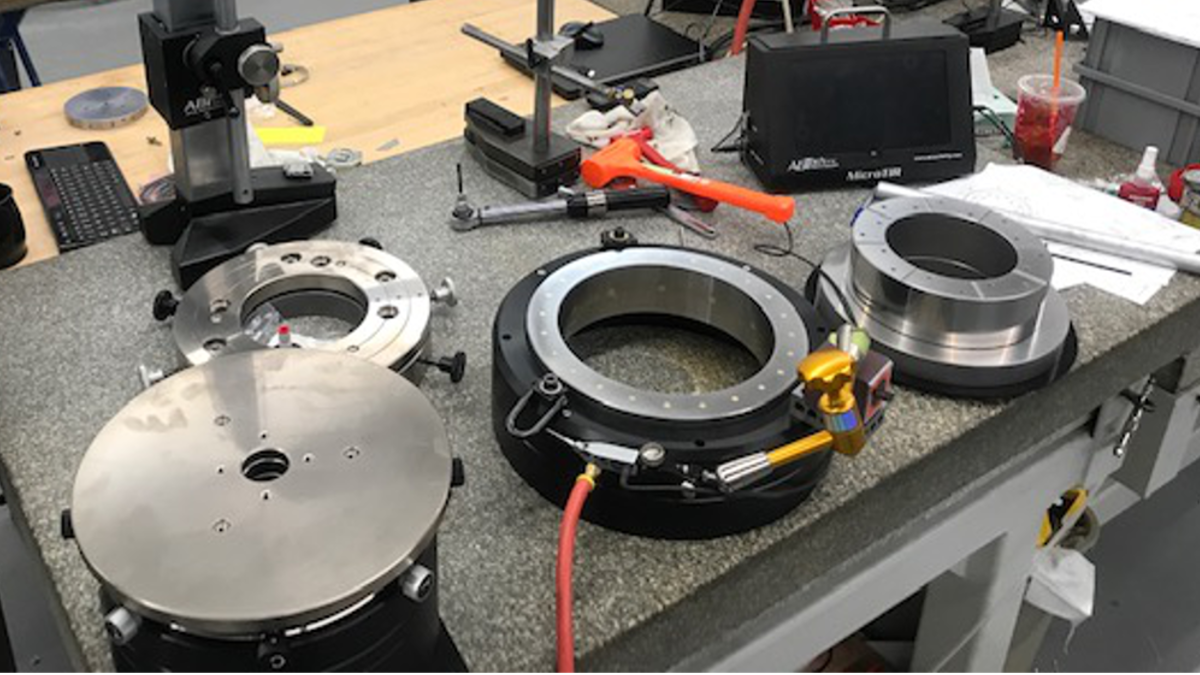

How to Maintain Accuracy in High-Capacity Turbine Rotor Assembly

The machining of large turbine workpieces creates unique challenges for the power generation industry.

High-capacity rotary tables, built for sub-micron measurement and runout inspection, are answering the call, breaking new ground for turbine rotor assembly and repair. These impressive platforms are capable of smoothly rotating turbine assemblies to confirm flatness and roundness to a sub-micron accuracy with absolute repeatability.

However, misalignment of these platforms can lead to costly, time-consuming teardowns.

In this whitepaper, we examine best practices for avoiding misalignment issues, including:

- The inspection and load capacity requirements of rotary tables.

- The precision thresholds it is possible to achieve with today’s technology.

- Which metrology and precision machining capabilities can help suppliers who make or maintain these heavy-duty pieces of equipment.

Looking for a Custom Designed Solutions?

Contact Our Team For a Custom Solution

See What Our Customers are Saying

"We use 2 ABTech air-bearing spindles with tip/tilt and centering capability in our facility. These units are used for precision assembly and final metrology. We have never had an issue with either one, and the ABTech team is a great partner for us. We will be adding more systems as our young organization continues to grow".

Jayson Tierson

President, Vertex Optics

See What Our Customers are Saying

“Thanks a lot for your help [with remote technical support provided for the system installed at the South Pole]. Your rapid, informative correspondence was invaluable. Hopefully I won't be bothering you with any further questions, but it's good to know you're willing.”

Morgan Hedges

Post-Doctoral Research Associate, Princeton University